Most people accept that major purchases in life — e.g., housing, automobiles, appliances — come with cyclical budgeting impacts that require amortizing costs over the long term, through savings or borrowing. Why should anyone expect the national water infrastructure to be any different?

The reality is that relatively long life-expectancies for major water infrastructure components — 100+ years on cast iron water mains, 40 to 50 years on water main valves, 15 to 20 years on water meters, etc. — have often insulated the public from major infrastructure investments. Today, infrastructure from the mid-20th-century suburban sprawl is reaching the end of its lifecycle, and no one is conditioned to thinking about reinvestment. People expect water rates to remain as consistent as the flow of water from their taps, simply because that’s the way it typically has been.

Sooner or later, however, upgrading aging water infrastructure becomes unavoidable. So how can the industry reconcile the inevitable conflicts between refurbishment and rate hikes?

Acknowledge The Elephant In The Room

According to a recent report from Bluefield Research, capital expenditures in the U.S. water and wastewater space are expected to be $638 billion over the next decade. Drinking water (44 percent) edged out wastewater (40 percent) as the market segment with the highest demand, and collection/distribution (55 percent) surpassed treatment facilities (25 percent) as the area of greatest need. Smart water hardware/software investment is forecasted to represent about $16 billion of the total expenditure.

While the needs for repair or replacement are obvious, the source of capital to achieve all those needs might not be quite as clear. That is where U.S. water utilities need to build a strong case in terms of educating ratepayers on the cost of meeting the challenges at hand — i.e., more complex source water issues, more demanding water quality standards, long-term investment and payback in water infrastructure, etc.

An important factor in the equation is educating customers on the value of water. In general, public opinion is already in favor of better infrastructure investment. A utility’s job is to leverage that sentiment when it comes to some specific projects that attempt to improve local infrastructure.

Replacement Vs. Upgrade

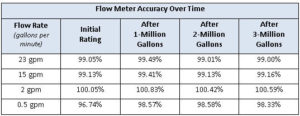

At some point, the outlay for maintaining old, failing infrastructure begins to cost more than amortizing the price of new infrastructure over the future life of that investment. This is particularly true in cases where metering inaccuracy compounds the cost of under-reported usage, day after day. Unfortunately, the greater the degree of error, the higher the cumulative losses will be over time. For example, a 2006 research report on meter accuracy and endurance testing showed how older metering technologies could struggle to maintain accuracy at low flows (Figure 1).

Figure 1. Meter testing shows that the margin of error is greatest at the lowest flow rates — both at the time of initial use and at various phases of service life. Over time, this error compounds non-revenue water (NRW) losses due to slow leaks.

An important part of a cost-effective solution involves researching technologies that can help pay for themselves in terms of reduced losses or improved operating efficiencies. Simply re-specifying the same old designs as replacements for aging or failing meters is not always the best choice. Upgrading to ultrasonic meters can provide greater accuracy over time and across all flow rates, to help defray the cost differential.

Significant efficiencies to be gained from infrastructure upgrades can also make those choices more cost-effective over the long term. Consider how a consumer-facing app instituted as part of a smart water strategy can educate consumers about their own water-use habits and provide resources — such as real-time alerts — to help them make better water consumption choices and reduce monthly costs.

Targeted Strategies For Upgrading To Major Advantages

As aging water meters approach their end-of-service-life, the new options for replacement are significantly better than those available when the old meters were originally installed. Knowing when to replace them, and which technologies can best pay for themselves in the long run, requires more than just rubber-stamping “or equivalent” to the original specification.

- Practice The Art Of Meter Triage. Differentiating commercial/industrial accounts from residential accounts, including the relative consumption by each type of account, can show how to “follow the money” when it comes to setting priorities for upgrading meter infrastructure. To identify the greatest short-term rewards, start by looking for metering inaccuracies at high-volume accounts where the NRW losses can quickly become the most costly.

- Compare The Benefits Of Technology Investments. Instead of simply specifying the next generation of mechanical meters, consider the payback of ultrasonic water meters vs. older metering technologies.

- Consider Low-Flow Metering Accuracy As A Complement To Smart Solutions. Ultrasonic water meters designed for residential and commercial/industrial applications provide accurate readings across all flow rates, to deliver quicker payback. As part of a smart water solution, they can also provide instant, more accurate feedback to help consumers manage their water use and lower costs (Figure 2).

Figure 2. Providing customers with instant access to individual water consumption patterns through online and mobile applications reduces customer service calls and provides insights they can use to manage their own water use and costs.

-

- Capitalize On System Solutions. Taking advantage of proven smart meter networks enables utilities to upgrade without requiring them to reinvent the wheel.

- Grow As You Go. Even if current financial circumstances do not allow for the most advanced upgrade, look for solutions that are sized for specific distribution needs, yet keep options open for future savings from a total smart water investment.

- Different Technology Executions Matter. Just as there are different technologies for different purposes, so too are there different executions of those technologies. Even within a given category — ultrasonic water meters, for example — performance results and maintenance requirements can vary from one manufacturer to the next. Be sure to review and appreciate the differences among major alternatives before choosing a particular technology.